SPS ® hydraulic shearing machine is driven by hydraulic pressure, and the swing shearing machine is pushed by an oil cylinder to achieve the cutting of the sheet metal. It is a common metal processing equipment mainly used to cut metal sheets of different thicknesses into the required length.The shearing machine is mainly composed of a base, hydraulic system, pendulum shearing structure, slider, pressure plate and other components.

Standard Components

| l Estun E21S Control Unit | l Taiwan HIWIN Ball Screw and Linear Guide Rail |

| l Germany Siemens Main Motor | l Germany EMB Pipe Connector |

| l Germany Rexroth Hydraulic Valve | l Japan NOK Sealings |

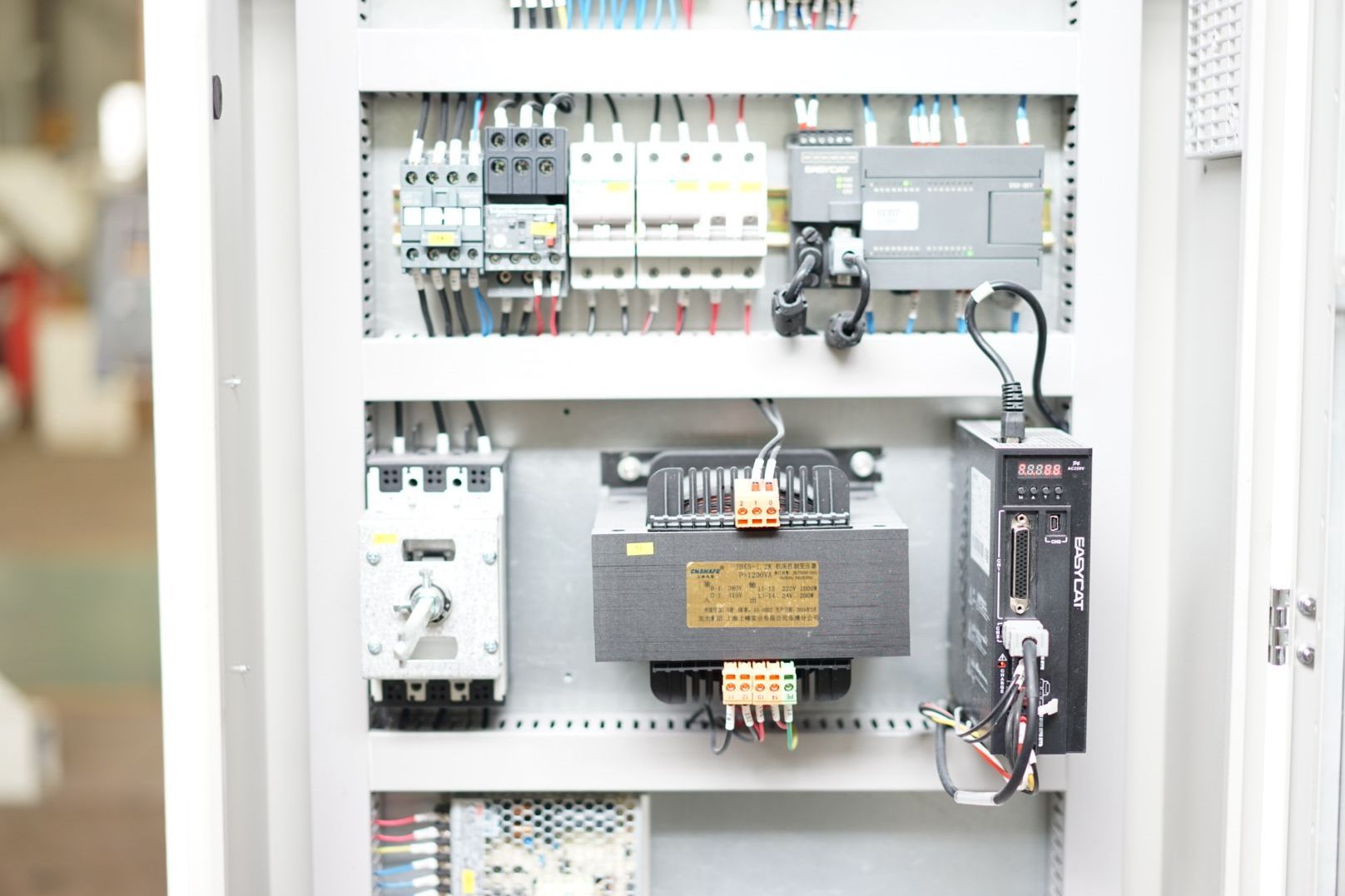

| l France Schneider Electrics | l Rear Safety Fence |

| l USA First/Sunny Oil Pump | l Korea Foot Pedal with Emergency Stop Button |

| l Taiwan Schihlin Inverter | l SPS Group Top and Bottom Blades |

Special CNC system for shearing machine, real-time display of rear gauge position, cutting counting function, real-time display of cutting quantity.

• Backgauge movement control

• Control AC motor or inveter

• 40 programs stored, 25 steps per program

• One key back-up/restore of parameters

Cutting Blade Gap

Blade gap is adjusted with a handwheel, which is fast, accurate and convienent.

Appropriate blade gap will achieve satisfactory shearing effect. The machine tool is equipped with a quick blade gap adjustment mechanism to meet the shearing needs of different plate thicknesses and materials. The blade gap can be adjusted by rotating the handwheel.

The rear stopper is controlled by a ball screw and linear guide rail, ensure machine positioning accuracy.

Estun company's supporting electrical cabinets are standardized and installed in accordance with DIN and ISO standards. They use the well-known French Schneider electrical appliances, which are safe and reliable, and easy to obtain accessories and replace. gantry processing center processing, with good stability and high precision.

More details of hydraulic shear machine